What safety measures should be included in excavator maintenance?

Daily Pre-Operational Inspections to Ensure Excavator Safety

Importance of pre-operational inspections in preventing on-site accidents

Checking equipment before starting work each day helps stop accidents from happening in the first place. When operators spot problems such as oil leaks around hydraulics, damaged electrical wiring, or tracks showing signs of wear early on, they can fix them before anything goes wrong. According to research from Heavy Equipment Safety Institute published last year, this proactive approach cuts down accident chances by almost 4 out of every 10 cases compared to waiting until something breaks down. Plus, regular morning checks mean fewer unexpected shutdowns because many mechanical troubles could have been avoided altogether if caught during routine inspection rather than after a breakdown occurs.

Essential checklist: Fluid levels, lights, and control systems

A systematic inspection should prioritize three critical areas:

- Hydraulic fluids & engine oil – Low levels accelerate component wear and reduce system efficiency.

- Warning lights & safety alarms – Intermittent alerts often signal early electrical system failures, with 72% showing prior warning signs.

- Control responsiveness – Delayed or sticky joystick responses may indicate hydraulic valve issues requiring immediate attention.

Using standardized maintenance checklists to enhance safety compliance

Equipment managers report a 45% improvement in inspection consistency when using digital checklists with photo verification. Standardized templates ensure technicians verify 22+ safety components, document fluid temperatures within operating ranges, and test emergency shutdown systems–improving both compliance and accountability.

Case study: Reducing downtime through consistent daily inspections

A 9-month trial across 142 excavators demonstrated that daily inspections significantly reduced key failure metrics:

| Metric | Improvement |

|---|---|

| Hydraulic failures | 52% |

| Track component replacements | 41% |

| OSHA-recordable incidents | 67% |

| Operators using tablet-based tools completed checks 28% faster while improving defect detection rates. |

Preventive Maintenance Strategies to Minimize Excavator Breakdowns

Understanding Routine vs. Preventive Maintenance in Excavator Upkeep

Routine maintenance includes regular tasks like fluid checks and filter replacements, while preventive maintenance involves proactive part replacements before failure occurs–such as changing swing bearings at 8,000 hours. This strategic approach reduces unscheduled downtime by 35–50%, according to manufacturer guidelines and industry data.

Recommended Maintenance Intervals Based on Operating Hours

Maintenance should align with meter readings:

- Hydraulic fluid replacement: Every 1,000 hours

- Track tension adjustments: Every 250 hours

- Boom pivot lubrication: Every 500 hours

Adhering to these intervals prevents 72% of hydraulic system failures, based on fluid analysis studies.

Best Practices for Tracking Excavator Maintenance and Inspections

Digital logs via CMMS (Computerized Maintenance Management Systems) automate service reminders and improve fault resolution. Technicians using cloud-based platforms resolve issues 28% faster by accessing real-time equipment histories and OEM-recommended protocols.

Data Insight: Up to 60% Reduction in Malfunctions With Preventive Maintenance

A 2023 analysis of 1,200 excavators found that scheduled preventive maintenance led to:

- 60% fewer hydraulic leaks

- 45% lower track system replacements

- 55% reduction in engine overheating

This results in an average savings of $18,000 per machine annually in repair and downtime costs.

Reactive vs. Preventive Maintenance: Evaluating Cost and Safety Trade-Offs

Reactive repairs cost 40% more over three years than preventive programs (Ponemon Institute 2023). More importantly, following OEM maintenance schedules reduces equipment-related injuries by 67%, according to OSHA compliance data, highlighting the critical safety advantage of proactive care.

Maintaining Hydraulic System Integrity and Fluid Efficiency

Role of hydraulic systems in excavator performance and operator safety

Hydraulic systems power 90% of excavator movements, enabling precise control of booms, arms, and buckets. According to the 2023 Fluid Power Institute study, 70% of hydraulic failures stem from contamination, which can compromise operator control and lead to sudden pressure loss–posing serious risks in active excavation zones.

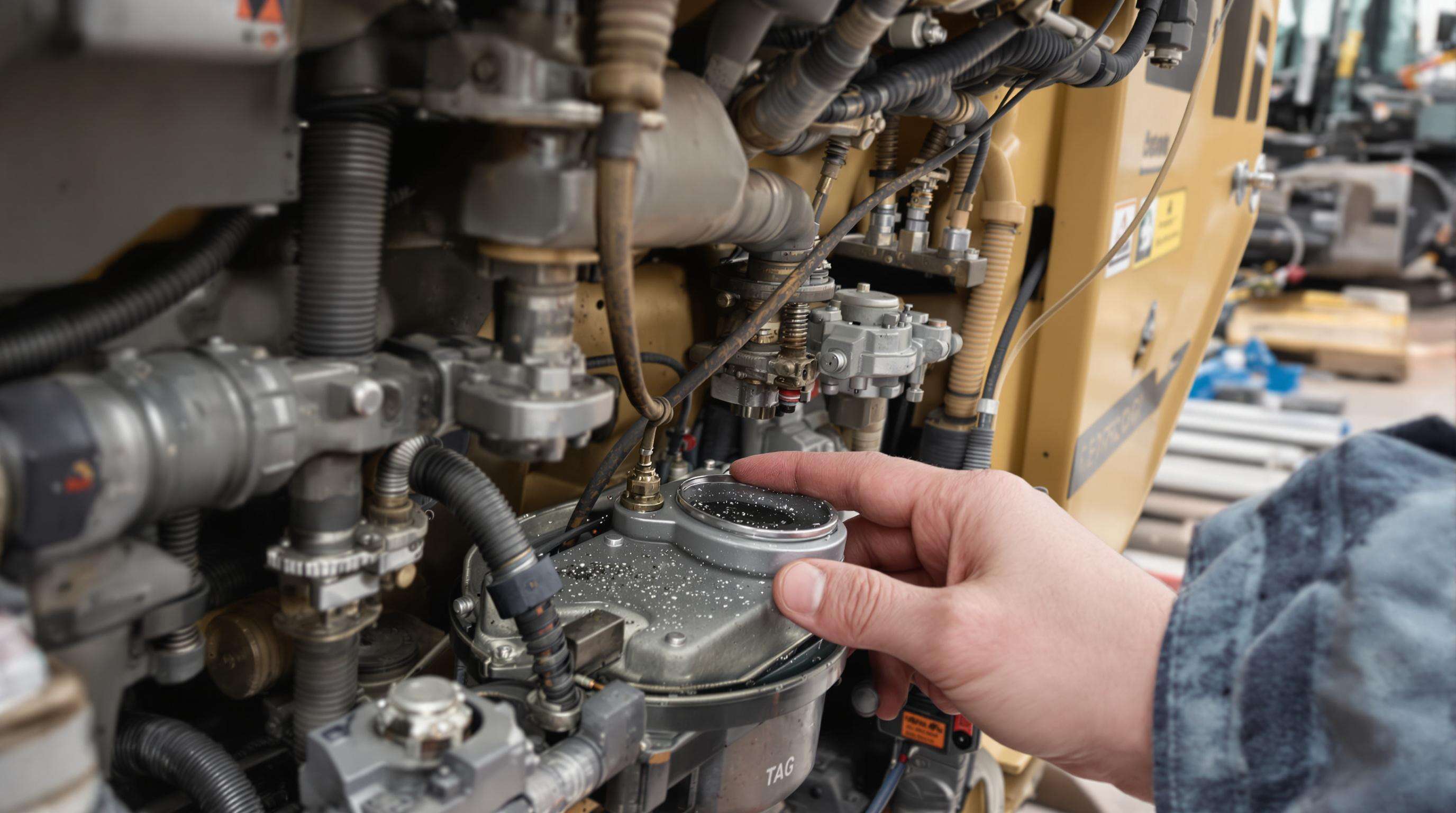

Monitoring hydraulic fluid levels and contamination risks

Follow a three-step inspection protocol:

- Check reservoir levels before each shift

- Inspect for metallic particles indicating internal wear

- Conduct monthly viscosity tests

Contaminated fluid reduces system efficiency by 30–50%. Inline particle counters enable 60% faster detection than visual checks, based on 2024 lubrication research.

Proper lubrication techniques for optimal hydraulic component function

Key best practices include:

- Using manufacturer-specified ISO-grade hydraulic oils

- Weekly purging of lubrication points with compatible greases

- Keeping cylinder rods clean to prevent abrasive damage

Excavators with automated lubrication systems experience 45% fewer joint failures than those maintained manually, according to a 2024 reliability study.

Emerging trend: Smart sensors for real-time hydraulic system diagnostics

Modern excavators increasingly use IoT-enabled sensors that:

- Monitor pressure fluctuations with ±2% accuracy

- Record fluid temperature every 15 minutes

- Detect microscopic contaminants via dielectric analysis

Field tests show these systems reduce hydraulic-related downtime by 40% and provide predictive alerts up to 120 hours before failure.

Inspecting and Replacing Worn Components to Ensure Structural Safety

Identifying wear in tracks, buckets, pins, and undercarriage components

Daily visual inspections help prevent structural failures. Key indicators include uneven track wear, eroded bucket teeth, and pin elongation exceeding 3%. Undercarriage wear should be measured against manufacturer thresholds, as 40% of structural failures originate from neglected track components (Heavy Equipment Safety Report 2023).

Proactive replacement strategies to extend excavator service life

Scheduled replacements based on operating hours maintain performance and reduce downtime. Replace bucket teeth every 500–700 hours and track chains at 10,000 hours to preserve digging force and mobility. Leading manufacturers recommend maintaining a spare parts inventory equal to 15–20% of fleet value to avoid project delays.

Critical structural checks: Detecting cracks or deformation in boom and arm assemblies

Quarterly non-destructive testing–such as magnetic particle inspection–is essential for load-bearing components. Industry-standard tolerance limits are:

| Component | Crack Tolerance | Deformation Limit |

|---|---|---|

| Boom Welds | 0.5mm | 2° angular shift |

| Arm Pivot Points | 0.3mm | 1.5mm elongation |

| Bucket Linkages | 0.7mm | 3% thickness loss |

Equipment exceeding these thresholds must be immediately quarantined until repaired.

Safety Protocols and Documentation for Maintenance Compliance

Enforcing Lockout-Tagout (LOTO) Procedures During Excavator Servicing

LOTO procedures isolate energy sources to prevent accidental startups during maintenance. Technicians must verify that hydraulic and electrical systems are fully de-energized using standardized locks and tags. LOTO oversights account for 18% of annual heavy equipment injuries, emphasizing the need for strict training and audits.

Required Personal Protective Equipment (PPE) for Maintenance Technicians

Essential PPE includes impact-resistant helmets, cut-resistant gloves, steel-toe boots, and high-visibility vests. Eye protection and respirators are required when handling hydraulic fluids or lubricants. Proper PPE reduces injury severity by 72% during maintenance tasks, according to occupational safety analyses.

Securing the Machine to Ensure Stability During Undercarriage Work

Before undercarriage inspections, deploy stabilizer legs or blocking devices. Working on uneven terrain increases tip-over risk by 34%, making proper stabilization critical. Always confirm the parking brake is engaged and the bucket is grounded to prevent unintended movement.

Maintaining Detailed Maintenance Logs for Regulatory Compliance and Audits

Digital maintenance logs support compliance with OSHA and ISO 45001 standards by recording inspections, repairs, and component replacements. Structured documentation systems reduce compliance errors by 40% and enhance audit readiness. Entries should include timestamps, technician signatures, and corrective actions taken.

The Importance of Immediate Repairs Upon Detecting Critical Faults

Delaying repairs for structural cracks or hydraulic leaks increases failure risk by 3.5x. Prioritize fixes for boom weld fractures, cylinder seal failures, or track tension issues to prevent catastrophic incidents. Post-repair load-testing verifies operational integrity before returning the machine to service.

FAQ Section

What are the key components of a daily pre-operational inspection for an excavator?

Key components include checking hydraulic fluid and engine oil levels, ensuring warning lights and safety alarms function correctly, and assessing control system responsiveness.

Why is preventive maintenance critical for excavators?

Preventive maintenance involves proactive part replacement and routine checks to prevent equipment failures, which help reduce unscheduled downtime and improve safety.

What are some common hydraulic system issues faced by excavators?

Common issues include hydraulic leaks, contamination, and inefficient fluid levels, which can compromise excavation operations.

How can digital maintenance logs enhance compliance and audits?

Digital logs record detailed inspection and repair data, improving compliance with safety standards and making audits more efficient.